Edited October 3, 2019

This is one article I was hesitant to write. It wasn't because I didn't know how to clean a muzzle loader. It's because there are so many ways to clean one and so many different opinions on the right way to do it. I just didn't want to gore anyone’s sacred cow. But I receive so many questions on this topic I decided it would be expedient to describe the method I use and why I use it. This method is one way to clean a muzzle loader. If you or someone you know has a different way and it works for you, that's great. However, if you experience hang-fires and misfires, or your final cleaning patch is still showing rust or fouling, you may want to reconsider your cleaning methods.

When I started shooting muzzle loaders in 1980 there was no internet to share information on and I was the only person I knew who owned a muzzle loader. The only information I had was the little booklet that came with my rifle kit. So I followed it and cleaned my rifle with hot soapy water and cotton cleaning patches followed with a good coating of gun oil. My rifle didn’t rust and it fired most of the time.

In those days the only shooting I did after I sighted in my rifle was to kill a deer or two with it every season. A pound of powder and a box of round balls lasted several hunting seasons. These days I shoot much more frequently. A little math shows I am putting 360 rounds on targets each year during monthly club shooting matches and rendezvous shoots. That number does not include shots fired in practice, sighting in, hunting, load development, or just for fun. When I started shooting more I began to experience a lot more “failure to fire” events. Commonly known as a misfire. In the early days I chalked those misfires up to the “unreliable nature of muzzle loaders”. But now I seemed to be the only shooter on the line experiencing regular misfires and it became obvious I wasn’t doing something quite right.

Searching out the cause of those misfires lead to the discovery that I wasn’t getting all the fouling cleaned out of the patent breech and flash channel of the gun. The hot water and cleaning patches were not cutting it. So I changed my cleaning routine and the misfires ceased, in that rifle. I continued to have misfires in other guns until I learned how they needed to be cleaned. And that is how I came to my present method of cleaning muzzle loaders. Misfires are now a thing of the past. It simply doesn’t happen.

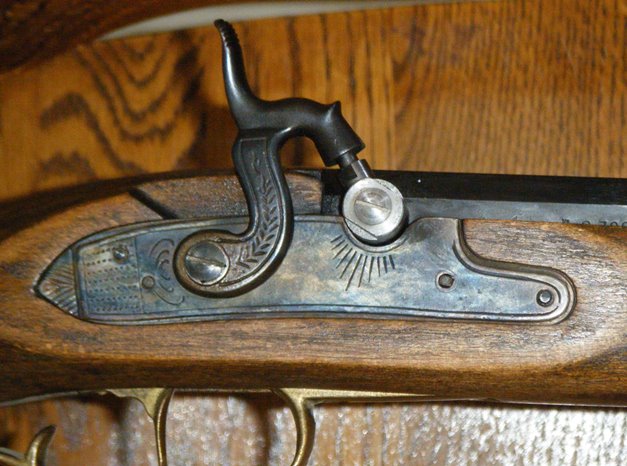

This is the lock of one of my CVA rifles. It is typical of percussion guns utilizing a drum.

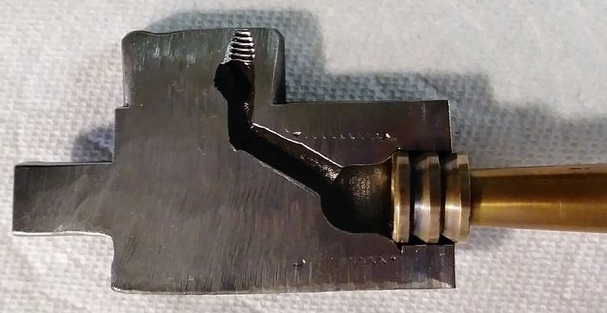

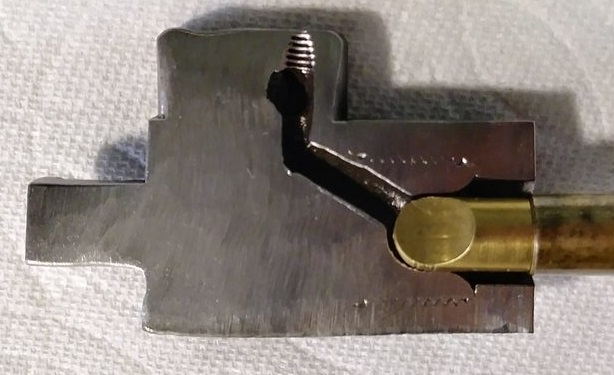

The next two photos are views of a drum removed from a CVA rifle.

In these views it is easy to see why a cleaning patch on a cleaning jag is not going to remove the fouling that collects inside the drum or on the threads which extend across the breech inside of the barrel.

Hot water flushed through the barrel simply does not remove all of that fouling. It may remove enough to get a few shots off but the remaining fouling that was left is going to absorb oil and cleaning solvent. Black powder residue mixed with oil makes tar. The pressures from firing the gun can blow this wet crud back into the drum and nipple. This obstructs the flash channel, the flame from the nipple doesn’t reach the powder charge, and the gun won’t fire.

To clean these areas of the gun I first use a black powder solvent to soften the fouling and then this phosphor bronze brush on the end of my cleaning rod to loosen it. Following that I remove the nipple and clean out screw and clean the inside of the drum with a pipe cleaner designed to clean the gas tube of AR-15 and M-16 rifles.

To clean these areas of the gun I first use a black powder solvent to soften the fouling and then this phosphor bronze brush on the end of my cleaning rod to loosen it. Following that I remove the nipple and clean out screw and clean the inside of the drum with a pipe cleaner designed to clean the gas tube of AR-15 and M-16 rifles.

These pipe cleaners have phosphor bronze or heavy plastic bristles worked into traditional pipe cleaners. Think of them as tiny scrub brushes with built-in mops. After the bristles loosen dirt and fouling, the mop holds all that crud and carries it out of the hole.

When it looks like I have removed all the fouling with solvent and brushes I then flush the barrel with hot water or solvent in the traditional way. Now that the fouling has been loosened the water will flush it out. Hooked breech barrels are easily removed from the stock for cleaning but I find that an unnecessary step for percussion guns.

A flush nipple pictured here works just as well, is less messy, and I don’t need to remove the barrel to clean it. Simply remove the nipple from the rifle and replace it with the flush nipple. Attach a piece of plastic tubing (available from aquarium supply stores) to the nipple, put the other end of the tubing into a bottle of water or cleaning solvent and pump it into the barrel with a wet cleaning patch on your cleaning rod. When the water or cleaning solution is coming out of the barrel clean remove the flush nipple and dry patch the barrel. When it’s dry oil it. Remember to clean the rifles nipple with a pipe cleaner or nipple pick.

Fouling around the outside of the barrel and on the lock is easier to remove because we can see it. How powder fouling finds it's way inside the lock is beyond guess, but it does. Remove the lock, clean and lubricate it. I use a nylon bristle brush and dental picks for this. Lubricate rotating parts with oil and sliding parts with a good gun grease.

This photo shows a percussion rifle with a patent breech. My Lyman Great Plains Rifle is of this style and was the gun that gave me the most trouble until I learned how to clean it correctly.

This cutaway photo is a patent breech from a Thompson Center rifle. It shows the flash channel and chamber inside the breech. Obviously, a typical patch jag will not enter these areas. Flushing water through the barrel will remove some, but not all of that fouling. That remaining fouling caused all kinds of headaches and frustrations for me at a State muzzle loading match once. An experience I do not wish to repeat.

By trial and error I discovered that a .38 caliber pistol brush fits nicely into the patent breech chamber of my .50 caliber Great Plains Rifle and removes that fouling. A .22 caliber rim-fire brush fits the patent breech of my Pedersoli Charles Moore Dueling pistol. Having a full set of different caliber sized cleaning brushes for my center fire guns on hand, I simply started with the smallest brush and tried it for fit in the patent breech of my rifle. I changed from smallest to larger sizes until I found the one that fit just right. (I did not want to try one too large and run the risk of getting a brush stuck in the breech.) There are scrapers available specifically made to fit inside the TC breech. Unfortunately, these may not fit other breeches because the dimensions of them are not uniformly consistent.

For example, when my custom Hawken rifle was built this cleaning jag and scraper were made to fit that particular breech before fitting it into the barrel.

To clean the chamber and flash channel of a patent breech, I cover the nipple with a folded cleaning patch and put the hammer down to hold it in place. Then I pour enough Moose Milk down the barrel to fill the patent breech and let it soak a bit. Next I scrub the breech chamber with the .38 caliber brush or a properly sized scraper and then empty the barrel. Following that I remove the nipple and clean out screw and clean the flash channel with pipe cleaners. Then I install the flush nipple and flush the barrel clean. Follow that up with dry patches and then oil the bore.

Flintlock guns are different. The breech face is flat. No patent breech or percussion drum to worry with. Simple, straight forward, easy. The patch jags I use have a concave shape to the face. These are great for loading a round ball without flattening or deforming it. However, the concave depression does not make good contact with the breech face and leaves a little hump of fouling there. The breech face scraper pictured here will remove that fouling.

So why, after a couple of months of shooting, did I suddenly start to have hang-fires and misfires. And where was this wet fouling I was finding in the pan after a shot coming from? It seems that the vent liner in my gun has a cone shaped opening on its inside. The design is to allow more of the main powder charge to come into closer contact with the hot gasses of the burning prime. This is supposed to make for a faster lock time. Okay, I buy that idea. But what was actually happening was the cone was collecting powder fouling into the recess and the cleaning patch on my cleaning jag could not wipe it clear. As you may have guessed by now, I was poking a hole through this crud with my vent pick so occasionally the gun would fire and the pressure was blowing some of that wet crud out of the vent and into the pan. The solution was to use a slightly larger than bore size, plastic bristle brush that gets into the vent recess and loosens the fouling that collects there. Since I started using that brush the gun fires every time and its lock time is just as fast as my percussion guns.

In my experience, putting the breech of the barrel into a bucket of hot soapy water and pumping it in and out with a patch on the cleaning jag was just not getting all the fouling out of the nooks and crannies. That fouling remained in the gun and collected the oil I was using to protect the barrel from rust. The oil mixed with the fouling and left a tar like crud in the guns. Sooner or later that crud builds up until it obstructs the flash channel and you get hang-fires and misfires. You may temporally remove some of that obstruction by clearing the vent or nipple with a pick and get the gun to fire but the root of the problem (the fouling) remains to cause another obstruction after a few more shots.

The answer to this problem for me was to use a black powder solvent (Moose Milk) that softens the fouling better than soap and water, an understanding of the peculiar nooks and crannies in each gun and finding brushes and tools the right shape and size to loosen it so it could be flushed out of the gun.

You can now pruchase Moose Milk on line. However, if you shoot as much as I you may want to mix up a batch. This particular recipe dissolves powder fouling well and will not harm the finish on your stock. The main ingredient is water, so I would not recommend letting it soak in your barrel any longer than you would allow it to soak in plain water.

In an empty 20 ounce bottle pour two ounces of Ballistol water soluble oil. Add one ounce of Lestoil liquid concentrated detergent. Add 16 ounces of filtered or distilled water. Shake well.

Yes, the mixture looks like milk. Don’t drink it. Clean your muzzle loaders with it.

I don’t know why this solution removes black powder fouling better than dish washing soap and water, but it does. Perhaps it’s in the formula of the Lestoil. I suspect that the Ballistol helps prevent flash rusting but it could be the combination of the two react differently on black powder residue. Perhaps a chemist among you would have the answer. All I know is, it works-don’t mess with it.

Proper cleaning to remove all traces of fouling will prevent 95 percent of hang-fires and misfires. In my experience the remaining 5 percent are caused by mistakes in the loading process and mechanical problems.

Remember that thing about oil and black powder fouling making tar? There is nothing better than a good gun oil to prevent rust and I recommend its use. Just remember to wipe it out of the bore before you load the gun. A cleaning patch saturated with rubbing alcohol will remove the last traces of it. Snapping two or three caps before loading will also burn the oil out of the drum and show that the flash channel is clear.

After you pour the powder charge down the barrel slap the side of the stock opposite the lock to settle the powder into the drum or patent breech.

Check that the flint is sharp and not loose in the jaws of the cock. Pick the vent.

Inspect your cap, sometimes the priming mixture falls out or wasn’t put in at the factory, if so toss that one in the trash. Pick the debris out of the nipple with a nipple pick or small wire.

With repeated use, a nipple can become mushroom shaped at its tip. The cap won’t seat firmly and the hammer drives it down without firing it. If this happens chuck the nipple in a drill, rotate it and file it down to size. Or toss it and replace it with a new nipple.

My stories of these different guns illustrate cleaning problems I encountered and how I solved them. Perhaps you have experienced some of the same problems and my solutions will help you. More likely, since all guns are different and seem to have their own peculiarities you will have to discover for yourself what works best for your gun. My hope is that sharing these experiences will offer some insight for you.

I know now that muzzle loading guns are not inherently unreliable. They are as reliable as the care you take in their loading and cleaning. So keep your powder dry and your rifle clean.